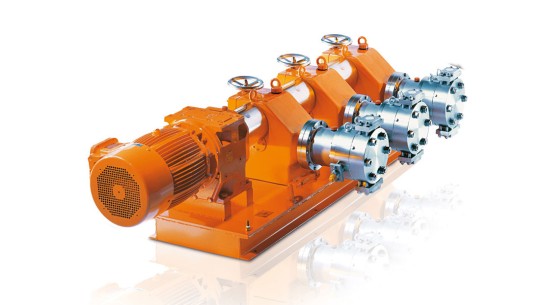

ORLITA Mf Hydraulic Diaphragm Metering Pump

Flows up to 2,200 gph (8,325 l/h) per head and pressures up to 11,350 psi

The hydraulic diaphragm metering pump ORLITA MF offers reliable dosing rates even under high pressure and has a modular construction, making it highly versatile. Thanks to its modular design, this pump is tailored to meet your requirements even at very high pump capacities.

Product description

Overview

High Accuracy Metering

The ProMinent Orlita Mf is a hydraulically actuated metering pump capable of reaching flows up to 2,200 gph (8,325 l/h) per head and pressures up to 11,350 psi (783 bar). A double PTFE diaphragm seals the liquid end from the hydraulic chamber while a unique cone valve design in the suction and discharge valve guarantees optimum accuracy.

The hydraulic chamber is equipped with internal pressure relief along with an automatic vent valve. These features allow the Mf to operate at high conditions and many different applications.

Your benefits

- In Accordance with API 675

- Accuracy ±0.5 %

- Multiplexing Available

- Flow rates to 2,200 gph per head

- Temperatures from -40 to 300 ˚F (-40 to 150 ˚C)

- Unique cone valves

- PTFE double diaphragm

- Diaphragm rupture control

- Operating Pressures to 11,350 psi

- Special connections as requested

- Heating or Cooling jackets

Application

Field of application

The following list is a general representation of basically suitable applications for this product. Please contact your personal representative to discuss the use of the product in your individual application.

- Glycol injection

- Catalyst injection

- Methanol injection

- Molten Sulfur

- LDPE Production

- Drag Reducers

Technical Data

Technical Details

- MfS 35 (MF2a) – stroke length: 0-20 mm, rod force: 3500 N

- MfS 600 (MF5b) – stroke length: 0-40 mm, rod force: 40,000 N

- MfS 1400 (MF6a) – stroke length: 0-60 mm, rod force: 60,000 N

- Stroke length adjustment range: 0 – 100% in operation and idle

- Stroke length adjustment: manually using manual adjustment wheel and scaled display (optionally with electric actuator or control drive)

- Metering reproducibility is better than ± 1% within the 10 – 100% stroke length range under defined conditions and with correct installation (API 675)

- PTFE multi-layer diaphragm with electrical diaphragm rupture warning / signalling system via a contact

- Integrated hydraulic relief and bleed valve

- Wetted materials: Stainless steel, special designs are available on request

- A wide range of power end versions is available: Three-phase standard AC motors, motors for use in areas at risk from explosion and different flange designs for use in customer-specific motors

- Degree of protection: IP 55

- Temperature range – 40 °C to + 150 °C

- Suction lift up to 8 m

- Design in compliance with API 675 among others

Actuation of ORLITA MF, MH, PS, DR

Control drive consisting of an actuator with servo motor and integral servo controller for stroke length adjustment via a standard signal. Standard current input 0/4 – 20 mA, corresponds to stroke length 0 – 100%, switch-over for manual/automatic operation; key switch for stroke adjustment in manual mode, mechanical position display of actual stroke length value output 0/4 – 20 mA for remote display. Control drives can also be designed with bus systems, like HART, PROFIBUS®, Fieldbus Foundation …

Variable speed motors with integrated frequency converter (identity code specification V)

Power supply 1 ph 230 V, 50/60 Hz (up to 3 kW). Externally controllable with 0/4 – 20 mA.

The following functions are integrated in the terminal box cover:

- Start/stop switch

- Switch for manual/external operation

- Potentiometer for speed control in manual mode

Speed controllers with frequency converter (identity code specification Z)

The frequency converter is accommodated in an IP 55-rated protective housing with integral control unit and main switch, suitable for max. 0.37/0.75 kW motor capacity.

Externally controllable with 0/4 – 20 mA or 0 – 10 V corresponding to 0 – 50 (60) Hz output frequency.

Integrated control unit with versatile functions, such as switching between external/internal control; frequency input using arrow keys with internal control, multilingual fault message display etc. and motor temperature monitoring (thermistor protection).

The speed controller assembly consists of a frequency converter and a variable-speed motor.