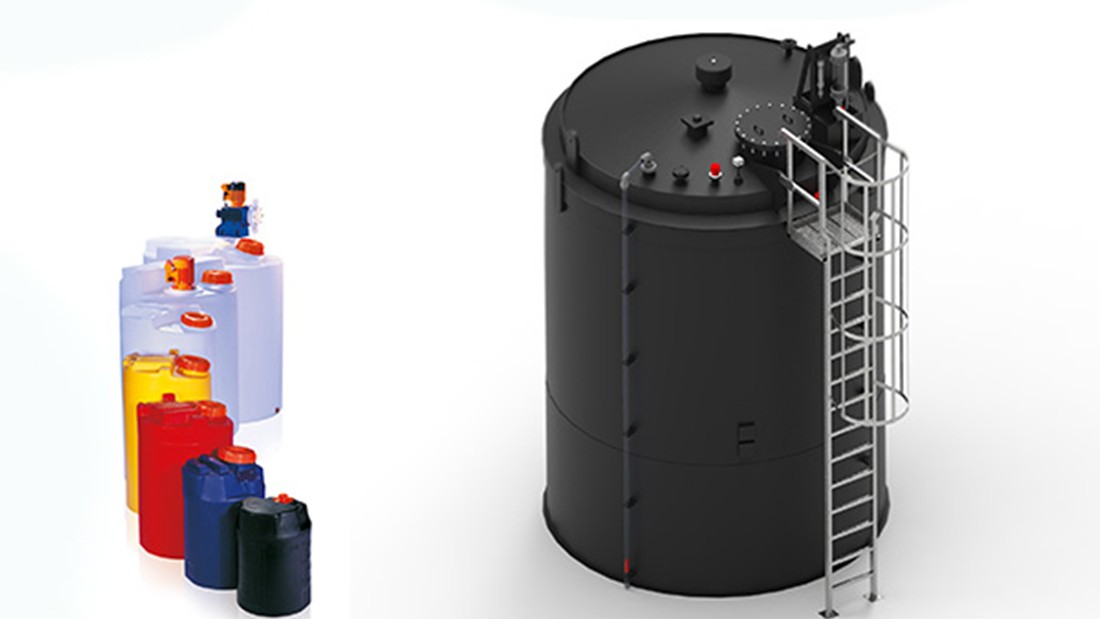

Storage Tanks

Nominal capacity: 9 – 264 gallons, in many different colors.PE tanks are produced in the rotational molding.Stackable containment bins

of PE come in various sizes with mounting ferules for pumps.

Product description

Overview

Safe and reliable handling of chemicals.

Production of plastic storage tanks to customers’ specific requirements and in accordance with the test certification. Constructional design and production are in compliance with the construction and test guidelines as laid down by the German Institute for Building Technology (DIBt).

After specification of the key requirements, including fill medium, installation place, storage and ambient conditions, as well as service life, a statistical calculation of the storage tank volume is produced which then provides the technical basis for detailed construction drawings.

PE-HD and PP plate material is primarily used.

Your benefits

- Excellent process reliability of the products, thanks to 25 years of experience in the engineering and production of plastic storage tanks.

- Wide diversity of installation components and storage tank accessories

- Selection of a suitable material after testing its chemical resistance and process-specific requirements.

- Excellent manufacturing quality by the use of state-of-the-art plastics processing machines

Application

Field of application

The following list of applications are general examples of generally suitable applications for this product. Please contact your local sales representative to talk about the applicable use of this product in your specific case / environment.

- Excellent process reliability of the products, thanks to 25 years of experience in the engineering and production of plastic storage tanks.

- Wide diversity of installation components and storage tank accessories

- Selection of a suitable material after testing its chemical resistance and process-specific requirements.

- Excellent manufacturing quality by the use of state-of-the-art plastics processing machines

Technical Data

Technical Details

- Wall-mounted: saves space

- Low-maintenance peristaltic pump for metering the liquid polymer

- Simple and fast to connect: requires only water, liquid polymer and power

- Automatic control

Technical Data

PE-HD Storage Tanks

- Test certificate Z-40.21-229 as per the WHG

- Design and production are in compliance with the construction and test regulations as laid down by the German Institute for Building Technology (DIBt)

- For operation at atmospheric pressure at an operating temperature of up to a maximum of 40 °C (media-dependent)

- Material polyethene PE-HD

- For installation outdoors or indoors

- For installation in earthquake zones with an appropriate technical design

- For chemicals as per the DIBt media list

- Ladder with small platform or stage available as an option

| Usable volume 95% fill level | Internal diameter | External diameter | Height of cylindrical section | Overall height | Weight empty |

|---|---|---|---|---|---|

| l | mm | mm | mm | mm | kg |

| 500 | 800 | 860 | 1,050 | 1,300 | 50 |

| 750 | 1,000 | 1,060 | 1,050 | 1,300 | 60 |

| 1,000 | 1,000 | 1,060 | 1,350 | 1,600 | 70 |

| 1,250 | 1,200 | 1,260 | 1,150 | 1,400 | 80 |

| 1,500 | 1,200 | 1,260 | 1,400 | 1,650 | 90 |

| 2,000 | 1,400 | 1,480 | 1,400 | 1,650 | 100 |

| 2,500 | 1,400 | 1,480 | 1,700 | 1,950 | 130 |

| 3,000 | 1,600 | 1,680 | 1,550 | 1,800 | 170 |

| 3,500 | 1,700 | 1,780 | 1,550 | 1,800 | 190 |

| 4,000 | 1,700 | 1,780 | 1,850 | 2,100 | 220 |

| 5,000 | 1,900 | 1,980 | 1,850 | 2,100 | 280 |

| 6,000 | 2,000 | 2,080 | 1,950 | 2,250 | 350 |

| 7,000 | 2,150 | 2,250 | 1,950 | 2,250 | 400 |

| 8,000 | 2,150 | 2,250 | 2,250 | 2,550 | 500 |

| 10,000 | 2,150 | 2,250 | 2,900 | 3,200 | 600 |

| 12,000 | 2,150 | 2,250 | 3,400 | 3,700 | 700 |

Common dimensions, special dimensions and other sizes on request.

PE-HD Collecting Pans

| Usable volume 95% fill level | Internal diameter | External diameter | Height of cylindrical section | Overall height | Weight empty |

|---|---|---|---|---|---|

| l | mm | mm | mm | mm | kg |

| 500 | 1,050 | 1,150 | 1,030 | 1,050 | 40 |

| 750 | 1,250 | 1,350 | 1,030 | 1,050 | 45 |

| 1,000 | 1,250 | 1,350 | 1,280 | 1,300 | 50 |

| 1,250 | 1,450 | 1,550 | 1,080 | 1,100 | 55 |

| 1,500 | 1,450 | 1,550 | 1,330 | 1,350 | 60 |

| 2,000 | 1,650 | 1,750 | 1,280 | 1,300 | 70 |

| 2,500 | 1,650 | 1,750 | 1,600 | 1,620 | 90 |

| 3,000 | 1,850 | 1,950 | 1,470 | 1,500 | 105 |

| 3,500 | 1,950 | 2,050 | 1,470 | 1,500 | 120 |

| 4,000 | 1,950 | 2,050 | 1,750 | 1,780 | 140 |

| 5,000 | 2,150 | 2,250 | 1,750 | 1,780 | 160 |

| 6,000 | 2,250 | 2,350 | 1,900 | 1,950 | 200 |

| 7,000 | 2,390 | 2,490 | 1,910 | 1,960 | 220 |

| 8,000 | 2,390 | 2,490 | 2,200 | 2,250 | 270 |

| 10,000 | 2,390 | 2,490 | 2,750 | 2,800 | 350 |

| 12,000 | 2,390 | 2,490 | 3,300 | 3,350 | 450 |

Common dimensions, special dimensions and other sizes on request.

Circular tanks

- Material polyethene PE-HD or polypropylene PP

- Floor design, flat floor, conical floor, angled floor

- Roof design, flat roof, conical roof or open, suitable for operation at atmospheric pressure at working temperatures of up to 80 °C

- Standard equipment: 2 lifting eyes above a round storage tank with a usable volume of 2000 l

| Usable volume 95% fill level | Internal diameter | External diameter | Height of cylindrical section | Overall height |

|---|---|---|---|---|

| l | mm | mm | mm | mm |

| 500 | 800 | 860 | 1,050 | 1,070 |

| 750 | 1,000 | 1,060 | 1,050 | 1,070 |

| 1,000 | 1,000 | 1,060 | 1,350 | 1,370 |

| 1,250 | 1,200 | 1,260 | 1,150 | 1,170 |

| 1,500 | 1,200 | 1,260 | 1,400 | 1,425 |

| 2,000 | 1,400 | 1,480 | 1,400 | 1,425 |

| 2,500 | 1,400 | 1,480 | 1,700 | 1,730 |

| 3,000 | 1,600 | 1,680 | 1,550 | 1,580 |

| 3,500 | 1,700 | 1,780 | 1,550 | 1,580 |

| 4,000 | 1,700 | 1,780 | 1,850 | 1,880 |

| 5,000 | 1,900 | 1,980 | 1,850 | 1,880 |

| 6,000 | 2,000 | 2,080 | 1,950 | 1,980 |

| 7,000 | 2,150 | 2,250 | 1,950 | 1,990 |

| 8,000 | 2,150 | 2,250 | 2,250 | 2,290 |

| 10,000 | 2,150 | 2,250 | 2,900 | 2,950 |

| 12,000 | 2,150 | 2,250 | 3,400 | 3,450 |

Rectangular tanks

- Material polyethene PE-HD or polypropylene PP

- Floor design, flat floor or angled floor, covering the entire area

- Roof design, flat roof or open, suitable for operation at atmospheric pressure at working temperatures of up to 60 °C

- Steel pipe reinforcement on all sides, with PE or PP jacket

- Standard equipment: 4 lifting eyes above a rectangular storage tank with a usable volume of 2000 l

| Usable volume 95% fill level | Inner dimensions (L x W x H) | Outer dimensions (L x W x H) |

|---|---|---|

| l | mm | mm |

| 500 | 950 x 750 x 750 | 1,100 x 900 x 770 |

| 750 | 1,000 x 1,000 x 800 | 1,150 x 1,150 x 820 |

| 1,000 | 1,000 x 1,000 x 1,060 | 1,150 x 1,150 x 1,080 |

| 1,250 | 1,250 x 1,000 x 1,060 | 1,400 x 1,150 x 1,080 |

| 1,500 | 1,500 x 1,000 x 1,060 | 1,750 x 1,250 x 1,090 |

| 2,000 | 1,500 x 1,250 x 1,130 | 1,750 x 1,500 x 1,160 |

| 2,500 | 1,750 x 1,250 x 1,210 | 2,000 x 1,500 x 1,240 |

| 3,000 | 1,750 x 1,250 x 1,450 | 2,000 x 1,500 x 1,480 |

| 3,500 | 1,750 x 1,500 x 1,410 | 2,000 x 1,750 x 1,440 |

| 4,000 | 2,000 x 1,500 x 1,410 | 2,250 x 1,750 x 1,440 |

| 5,000 | 2,500 x 1,500 x 1,410 | 2,750 x 1,750 x 1,440 |

| 6,000 | 2,500 x 1,750 x 1,450 | 2,750 x 2,000 x 1,480 |

| 7,000 | 2,500 x 1,750 x 1,700 | 2,750 x 2,000 x 1,730 |

| 8,000 | 2,500 x 2,000 x 1,700 | 2,750 x 2,250 x 1,730 |

| 10,000 | 3,000 x 2,000 x 1,760 | 3,350 x 2,350 x 1,800 |

| 12,000 | 3,500 x 2,000 x 1,810 | 3,850 x 2,350 x 1,850 |

| 15,000 | 4,000 x 2,000 x 2,000 | 4,350 x 2,350 x 2,050 |